M.E.G.A. designs and manufactures special fittings for critical applications in Oil & Gas, chemical, offshore, subsea, power generation, and nuclear sectors. Our production is entirely in-house, with complete control of forging, machining, heat treatment, welding, cladding, and certified laboratory testing.

Thanks to this integrated approach, we provide tailor-made components up to 80” and large-scale fittings in every steel grade, including stainless, duplex, nickel alloys, and titanium.

On this page:

- Special tee fittings

- Inserts

- Nozzles

- Flanged products

- Spools and Wyes

- Misalignment and Special Flanges

- Forged Seamless Pipes

- Other components

- Custom prototyping for special pipe fittings and engineered components

- Applications and sectors

- Why choose M.E.G.A.

- FAQs

Special projects

Special tee fittings

A tee is a T-shaped fitting used to join or divide fluid flow. Available as equal tee or reducing tee. Special executions include:

- Barred tee – fitted with restriction bars to allow pig passage

- Flow tee – oversized outlet tee with guide tube for pig passage and flow control

- Target tee – forged with a closed end, suitable for erosive flow conditions

Inserts (Megalets, Latromegalets, Elbomegalets, Insert Megalets BW)

M.E.G.A. inserts are integrally reinforced branch connections.

- Insert Megalet (BW): low Stress Intensification Factor (SIF), full NDE control, fatigue resistance, and compliance with ASME B31.3. Available in butt-weld, socket-weld, threaded, and flanged execution.

- Designed for severe service conditions (Type I and II) and validated through FEM analysis and proof tests.

Nozzles

Flat fan, full cone, hollow cone, solid stream, air atomizing, special purpose nozzles.

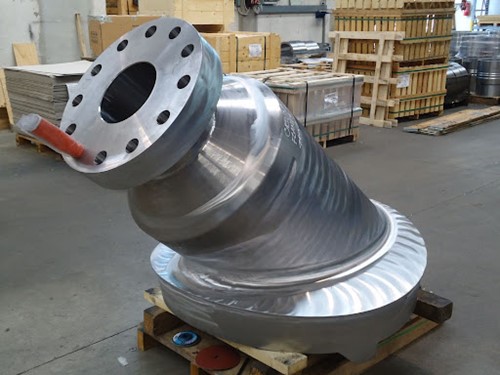

M.E.G.A. produces customized reinforced nozzles for heat exchangers, pressure vessels, and reactors. These nozzles can be designed as inclined flanged reinforced types and are used in high-pressure and high-temperature applications, with weights up to 40 tons.

Flanged products

Flanged Tee / Nipoflange / Flanged Spool / Flanged Nozzle.

Special flanged outlets provide branch connections with flanged terminations. They reduce installation cost, improve fatigue resistance, and are available from 1/2” to 12”, with pressure ratings from Class 150# to 2500#, RF or RTJ. Designed in accordance with ASME B31.3 and ASME B16.5.

Spools and Wyes

Piggable Wyes (asymmetric & symmetric)

Y-shaped fittings allowing pig passage at tie-in connections. Designed with FEM validation, compliant with ASME VIII, B31.4, B31.8, and DNV standards. Manufactured from forged ingots with optional CRA cladding. Fully piggable in both directions.

Spools

Misalignment and Special Flanges

Misalignment Flanges

Special flanges allowing up to ±10° misalignment between two pipelines. Equipped with spherical central body, rotating flanged rings, and metal-to-metal gasket seal. Designed according to ASME B16.5, B16.47, B31.3, API 6A, MSS SP-44. Validated with FEM analysis.

Anchor Flanges

Anchor flanges are special components used to restrain pipeline movement, absorbing axial forces generated by pressure and temperature variations. They are commonly applied in long pipelines or subsea applications.

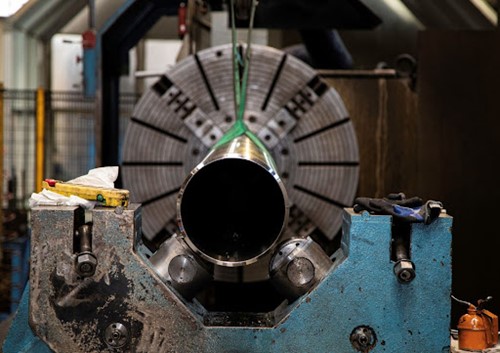

Forged Seamless Pipes

M.E.G.A. produces forged seamless pipes up to 48” and 12 m length. Manufactured through trepanning, CNC boring, and internal grinding for precision. Available with CRA cladding, hydrotested, and compliant with API 5L and other international specifications.

Other special components

- Bulkhead, Triple tees, Pig receiver, Elbow tees, Double crosses, Sweepolet, Welded valves (assembled with fittings, not produced internally), Double barred tees.

Applications and sectors

Our special fittings in piping are designed for high-demand industries and critical projects:

- Oil & Gas – onshore, offshore, subsea pipelines and refineries

- Petrochemical plants — M.E.G.A. manufacture chemical resistant pipe, tube, and pump fittings that meet very high-quality and security control standards.

- Power generation – conventional and nuclear power stations

- Renewables – wind energy components

- Nuclear plants — Piping and fittings are a primary component of nuclear power plant infrastructure, being the channels through which the essential fluids for the production of nuclear energy flow.

- Subsea and offshore installations — Working underwater requires a safe and reliable processing capability. M.E.G.A. S.p.A. is well aware of the stringent requirements necessary for products installed in surface or deep waters. Its products are fully compliant, most notably with DNV requirements.

Why choose M.E.G.A.

- Engineering expertise: FEA analysis, CAD-CAM design, tailor-made solutions.

- Internal production: forging, machining, heat treatment, cladding, welding (TIG, MIG, submerged arc), surface treatments, and accredited NDE inspections.

- Certified quality: compliance with ASME B31.1, B31.3, B31.4, B31.8, ASME BPV, PED, RCC-M, EN 13480, EN 10253, supported by FEM calculations.

- Advanced cladding division: CRA overlays with TIGer and GMAW processes for corrosion resistance.

- Flexibility: no design limit—manufactured upon customer specification in any steel grade.

M.E.G.A. is your trusted partner for the design and production of special pipe fittings tailored to the most demanding projects. From engineering support with finite element analysis to complete in-house manufacturing and certified testing, we guarantee performance, reliability, and compliance with international standards.

Get in touch with our team to discuss your project requirements and discover how M.E.G.A. can support your applications in Oil & Gas, Power Generation, Subsea, and Renewables.

FAQ – Special Pipe Fittings & Custom Engineered Components

1. What are special pipe fittings?

Special pipe fittings are custom-engineered components designed for applications where standard fittings are not sufficient. They are typically used in high-pressure, high-temperature, corrosive, or subsea environments and are manufactured according to project-specific geometries, materials, and international codes such as ASME, API, and DNV.

2. When do I need a custom or engineered fitting instead of a standard fitting?

Custom fittings are required when the piping layout includes non-standard dimensions, special angles, high fatigue loads, piggable configurations, or when the service conditions demand materials or reinforcements beyond standard catalog items. Projects like refineries, hydrogen, LNG, subsea tie-ins, and nuclear systems often require engineered solutions.

3. Which standards apply to special pipe fittings?

Depending on the application, special fittings must comply with various international codes such as ASME B31.1, B31.3, B31.4, B31.8, ASME VIII, ASME B16.5, API 6A, DNV-ST-F101, EN 13480, RCC-M, and others. M.E.G.A. designs and manufactures components in full compliance with the required code and provides complete certification and testing documentation.

4. Which materials are used for special fittings?

Special fittings can be produced in carbon steel, alloy steel, stainless steel, duplex and super-duplex, nickel alloys (like Inconel), titanium, and CRA-cladded materials. The choice depends on pressure, temperature, corrosion risk, and project specifications.

5. Can special fittings be designed for piggable systems?

Yes. Components such as piggable wyes, barred tees, flow tees, and flanged outlets can be engineered for full bidirectional piggability. FEM validation, guide bars, oversized outlets, and reinforced geometries ensure smooth pig passage and structural integrity.

6. What is the maximum size of special pipe fittings produced?

M.E.G.A. manufactures custom fittings up to 80”, forged seamless pipes up to 48”, and special components up to 12 m in length and 40 tons in weight—depending on geometry and material.

7. Do you provide NDE and pressure testing?

Yes. All special fittings undergo complete NDE (UT, PT, MT, RT) and hydrostatic testing in accordance with ASME and client specifications. Additional tests (impact, corrosion, metallography) can be performed in our certified in-house laboratory.

Our certifications

Having the right certifications is essential to ensure the highest-quality production while respecting the environment.

Learn more