Nuclear Plants

Certifications

Standard

Object

Emitted by

Standard

NNSA China qualification for fittings

Object

Products and quality system

Emitted by

NNSA

Standard

ASME III NCA 3800

Object

Quality system

Emitted by

ASME

Standard

ASME B31.1, B31.3, B31.4. B31.8, Sect. VIII...

Object

Self-reinforcing inserts and branch outlets for pressurised equipment

Emitted by

TUV

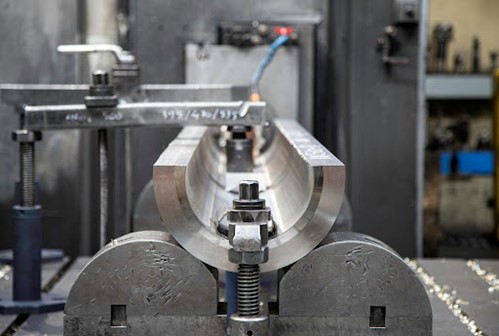

However, manufacturing nuclear fittings requires very high and specific quality control standards. M.E.G.A. has been recognized as an ASME Material Organization, frequently works according to RCC-M standards, and has been approved by the Chinese NNSA, giving us the ability to supply products fully in accordance with the restrictive requirements of the nuclear sector.

With international experience in supplying nuclear fittings, we are able to respond promptly to each customer's needs, even the most specific ones. We take care efficiently and flexibly of the entire production cycle of each nuclear fitting, starting from forging to the final stage of testing and inherent certifications.

Types of nuclear fittings

Depending on your needs, M.E.G.A. manufactures and provides you with different types of nuclear fittings. Below you will find a list of our products for nuclear plants with their main characteristics.

Standard nuclear fittings

Standard fittings and unions are high-quality products suitable for the nuclear industry. Threaded or socket fittings, as well as swage nipples, are available in all the variants provided by the standards: threaded, BW, flat, and eccentric.

For nuclear plants, fittings are provided in carbon steel, stainless steel.

Discover our standard fittings

Megalets

Among the branch outlet nuclear fittings, the so-called megalets are the most used products, self-reinforcing branch outlets with a 90° conformation to the main pipeline. Depending on the different configurations, they are divided into:

- Latromegalet: can be installed to obtain a branch outlet with an angle other than 90°;

- Elbowmegalet: can be mounted on a curve;

- Insert megalet: that can be welded directly inside the main pipe.

- All these types can be supplied with butt weld (BW), socket-weld, threaded and also flanged ends.

In order to satisfy the security standards of a nuclear plant, these fittings are required to undergo the certifications we will mention below.

Discover our branch outlet fittings

Special nuclear fittings

This product line includes special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements of the nuclear industry.

Seamless pipes for nuclear plants

M.E.G.A. is able to produce seamless nuclear fittings up to 11000 mm in length and 1400 mm in outside diameter, specifically designed for nuclear plants. The special machining process enables M.E.G.A. to produce special SMLS seamless tubes with extremely small thicknesses (up to 20 mm - depending on other dimensions) and large diameters, available in different materials.

Welded nuclear fittings

We have a special department for welding fittings. Here we make spools and other special assemblies for the nuclear industry, suitable to meet customer requirements with certified nuclear products guaranteed by our quality system. Welding can be performed on all machined products (inside/outside of forgings, ring joint seats of flanges, etc.).

Our certifications in manufacturing nuclear fittings

M.E.G.A. has the NCA certification issued by ASME (American Society of Mechanical Engineers, the most influential association for the regulation of the nuclear sector). N-type Certificates of Authorization means that a Certificate Holder has been through a rigorous survey to verify the adequacy and effective implementation of the quality assurance program. This certification allows M.E.G.A. to certify and stamp newly constructed components, parts, and appurtenances used at a nuclear facility with the Certification Mark in accordance with Section III of the ASME BPVC.

We also work in accordance with RCC-M standards and TUV standards, which states the compatibility of our nuclear fittings, self-reinforcing inserts and branch outlets for pressurized equipment in nuclear sites. Eventually, we are also certified by NNSA with the NNSA China qualification for fittings.