Welding services

On this page:

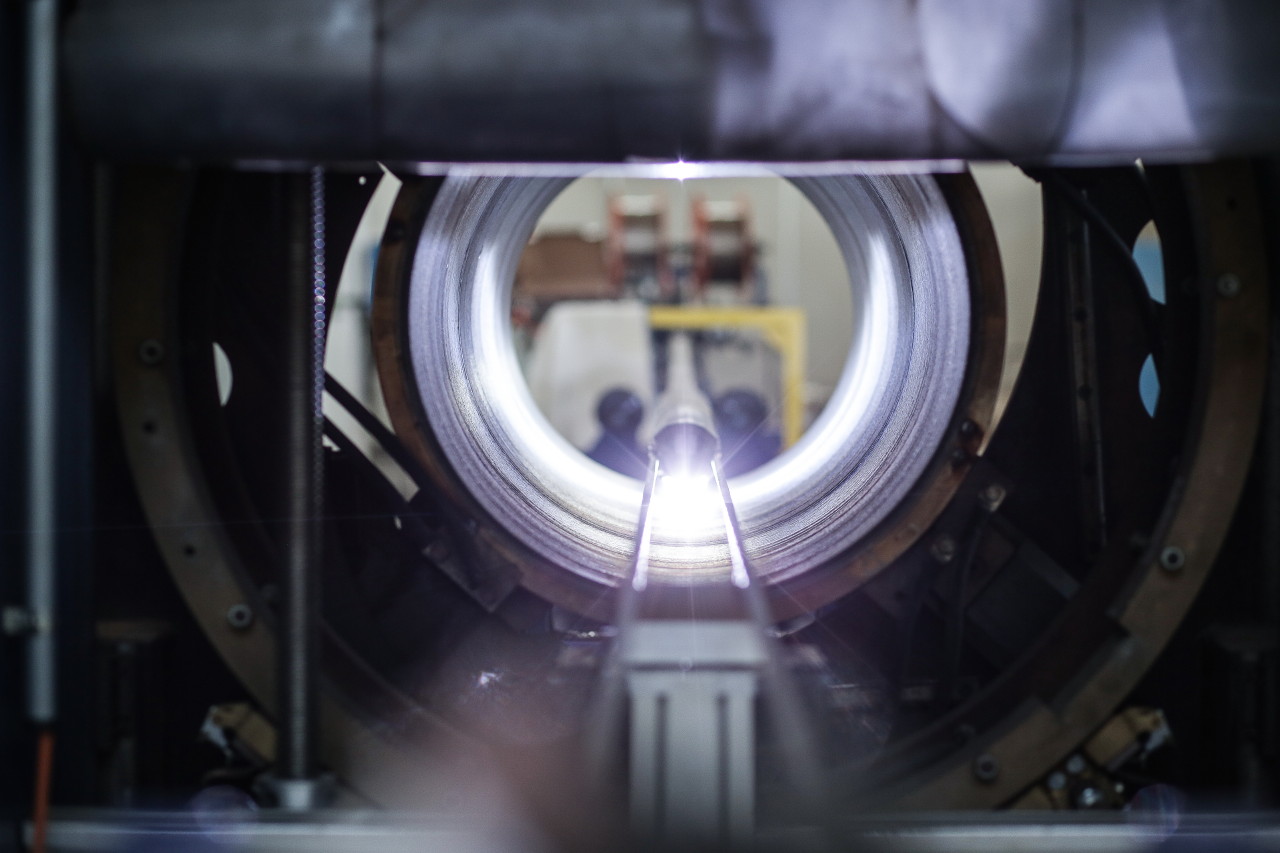

MIG welding: everything you need to know

MIG is the mainly used method to obtain customized parts according to customers' requirements.

MIG welding is a continuous wire arc welding process consisting of a metal under gas shielding (GMAW, or Gas Metal Arc Welding). To heat metals and enable welding, MIG uses the power given off by an electric arc that shoots between the electrode (called filler material) and the metal itself. The electrode is an endless type; during the process, it is fused together with the edges of the metal to be welded. Eventually, it is a type of welding that takes advantage of the action of certain gases. By means of a cylinder, gases are inserted into the welding bath that protects the arc and the welding zone from the influences of the surrounding atmosphere.

Would you like to know more about M.E.G.A. MIG welding services?

Welding service suppliers: which metals can we form?

M.E.G.A. manufactures aluminum, carbon steel, stainless steel, duplex, super duplex stainless steel, nickel alloys, copper alloys, titanium, and other metallic materials fittings. All our products can be supplied seamlessly, but also welded and coated upon request.

Aluminum welding service

Aluminum fittings, nozzles, pipes, olets, and other fitting items can be manufactured by the welding process to obtain a particular form or geometry. Aluminum is a soft, extremely porous metal that requires careful weld joint preparation to remove oxide or other surface impurities before welding. Aluminum and aluminum alloys have a low melting point, so the welding process must be run carefully. M.E.G.A provides certified welding services specifically for aluminum, ensuring results are free of porosity and deformation. Years of experience, state-of-the-art equipment, and inspection services meet or exceed the requirements of the most challenging projects.

Titanium welding service

M.E.G.A. is a certified titanium welding services company that manufactures customized fittings upon request. We can realize and weld elbows, tees, reducers, caps, and special pieces from ½” to 56”, with no thickness limits. In particular, titanium is a hard metal with a high melting point, that needs technical expertise to be formed. Fittings for the chemical and petrochemical industry, nuclear industry, and subsea installations are usually made of titanium or stainless steel.

Copper alloy welding service

M.E.G.A. welding services include copper alloy forming. Copper is the most widely used nonferrous metal in metallurgy after aluminum due to its excellent properties. The high conductivity of copper makes it difficult to weld. Therefore, in the case of thick metal sheets, pre-heating must be performed at least toward the beginning of the weld seam. Thanks to decades of experience in the industry, M.E.G.A. can use different techniques for copper and nickel welding: laser, TIG, MIG/MAG, and resistance welding.

Steel and stainless steel welding services

Steel and stainless steel welding are carried out with different methods: MIG/MAG, TIG, or coated electrode welding. M.E.G.A. is a certified welding services supplier, forming tailor-made stainless steel fittings for oil&gas, nuclear, and power industries. Our service is among the most flexible: we ensure both small and large fittings production for a large number of sectors.

M.E.G.A. is a certified welding company for forming fittings and special items.

Contact us for a free quote!

Special welding services

M.E.G.A. has high-tech, state-of-the-art welding systems that enable highly functional and safe results, allowing us to perform special metal welding. Our finishes ensure precision in every detail and an established development and work methodology. Our specialized staff has profuse experience in special welding processes for fittings and special items.

Our work process includes:

- Design and feasibility study

- Sampling

- Applied technology

- Processing

- Control

M.E.G.A. welding products

We manufacture spools and other special assemblies to meet customer requirements with certified welds guaranteed by our quality system. For instance, cladding can be carried out on all machined products (inside/outside forgings, ring joint seats of flanges, etc.).

Our welded outputs include:

- Spools

- CladdingsFittings

- Olets

- Nozzles

- Branch outlets fittings

- Nipolets

- Elbows

- Heavy wall fittings

- Flanges.

Every item can be requested on standard measures or on a tailor-made project.

Choose the fittings available ex-stock or design a special piece for your projects with our technical department.